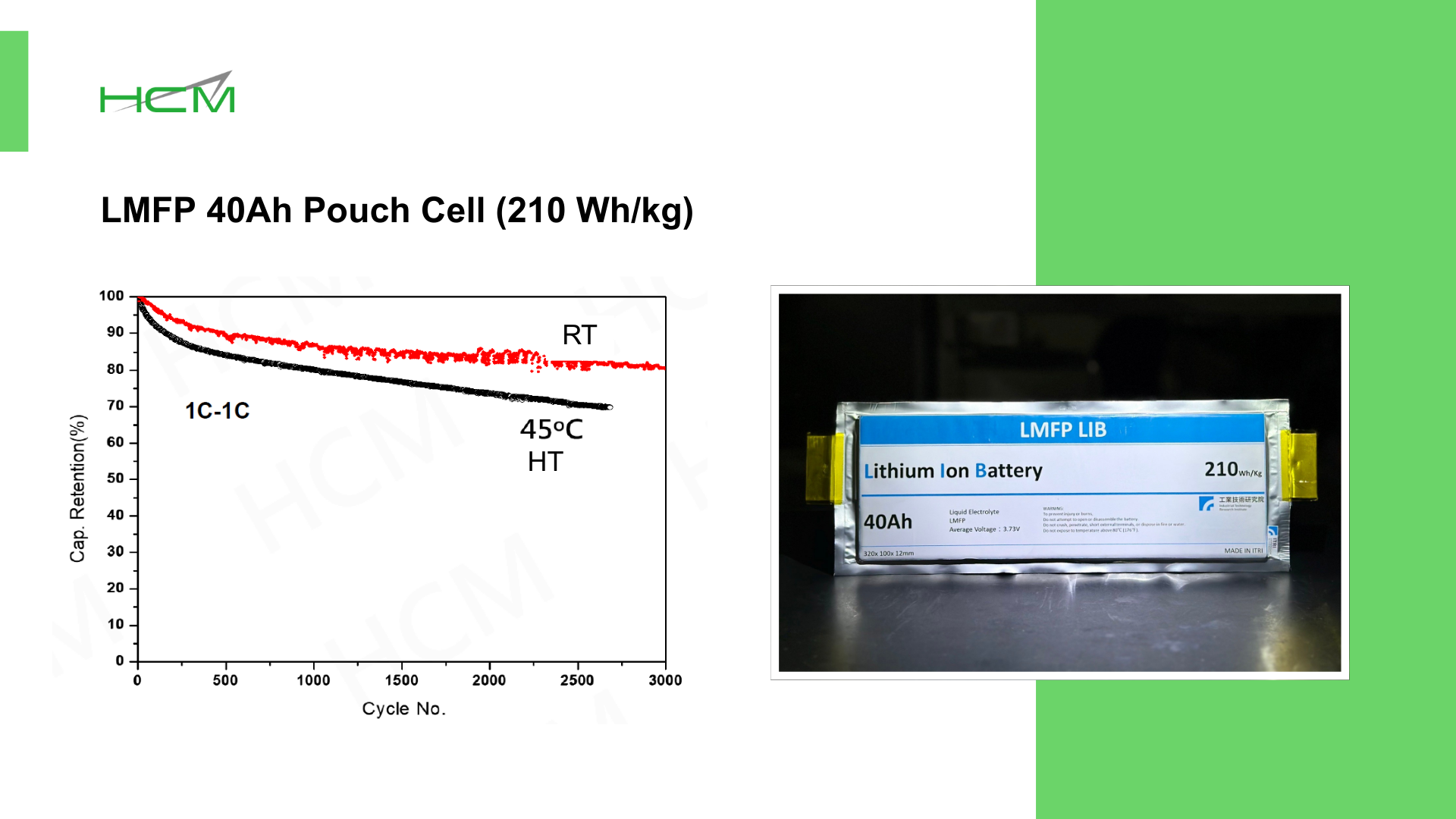

The Equipment Behind Next-Gen LMFP

At HCM, innovation isn't just about chemistry. It's also about engineering the right equipment to unlock performance.

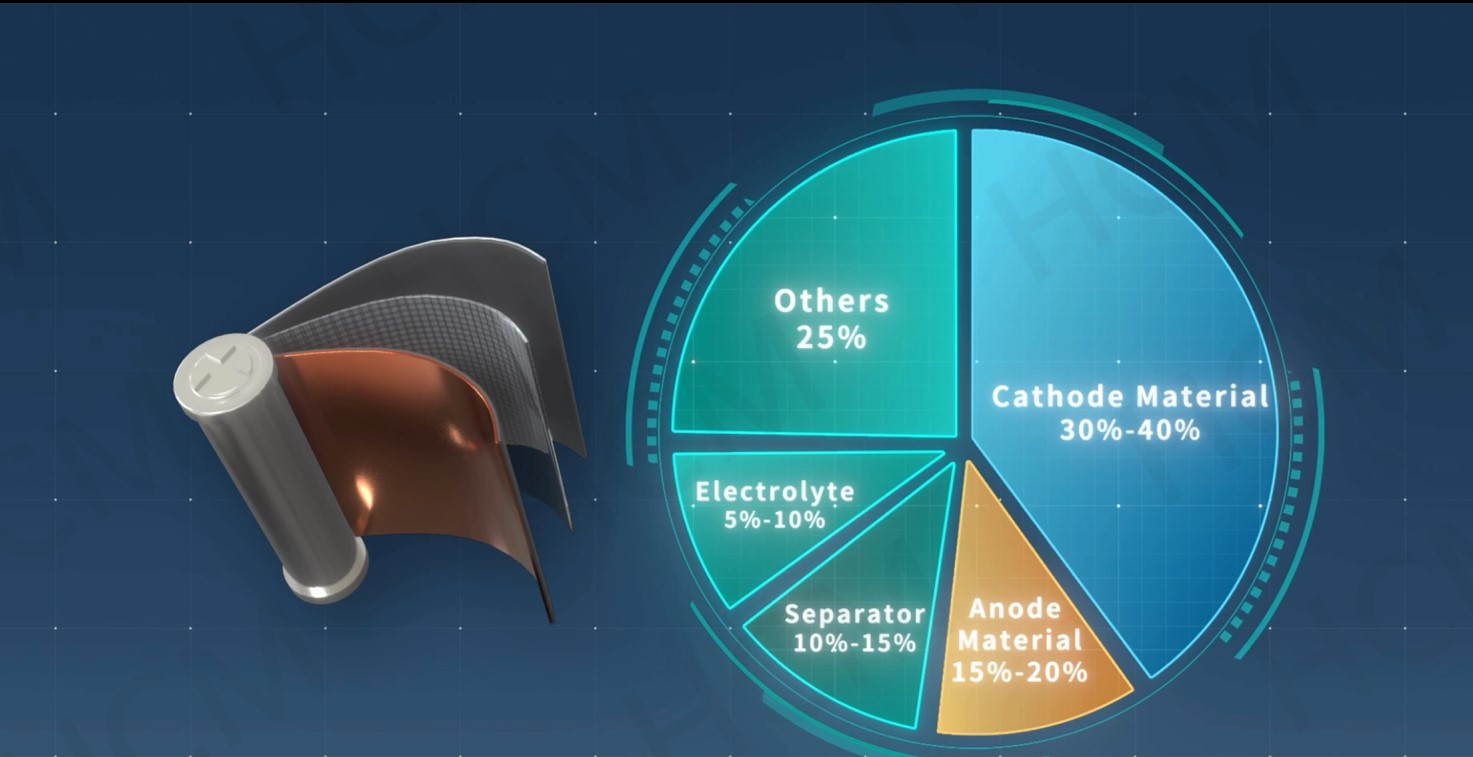

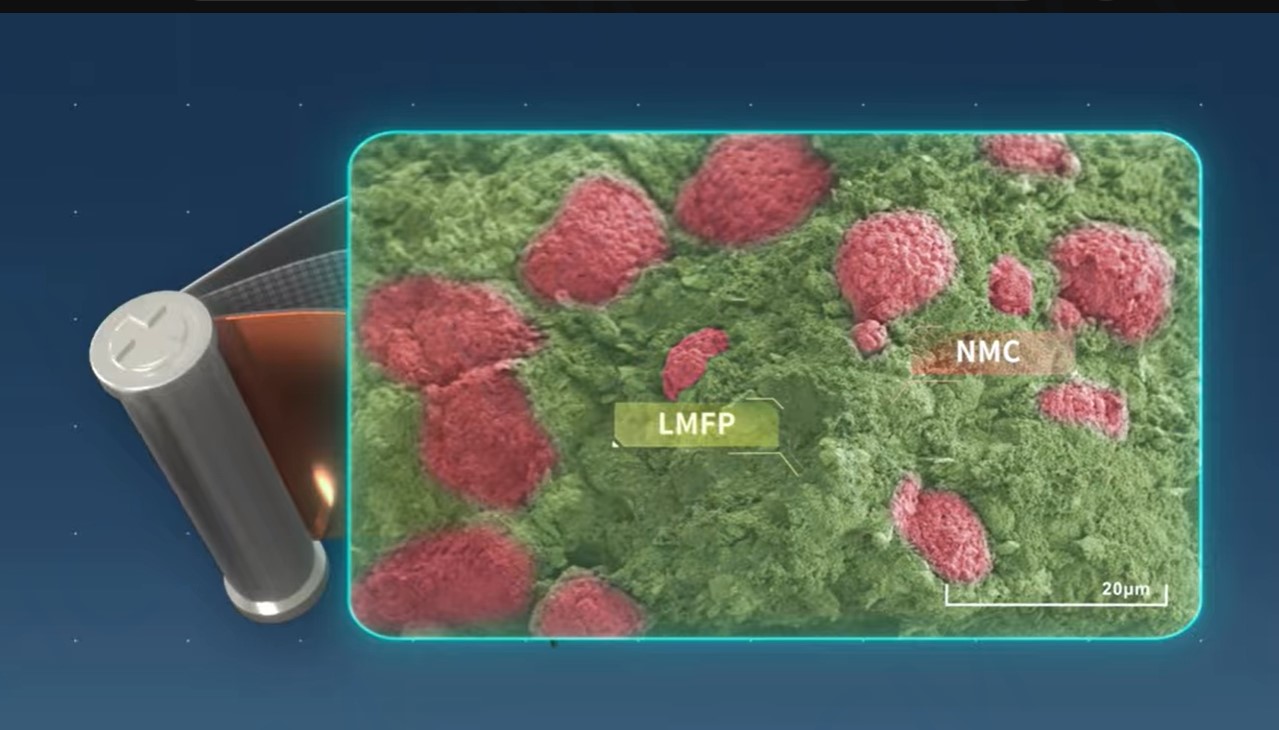

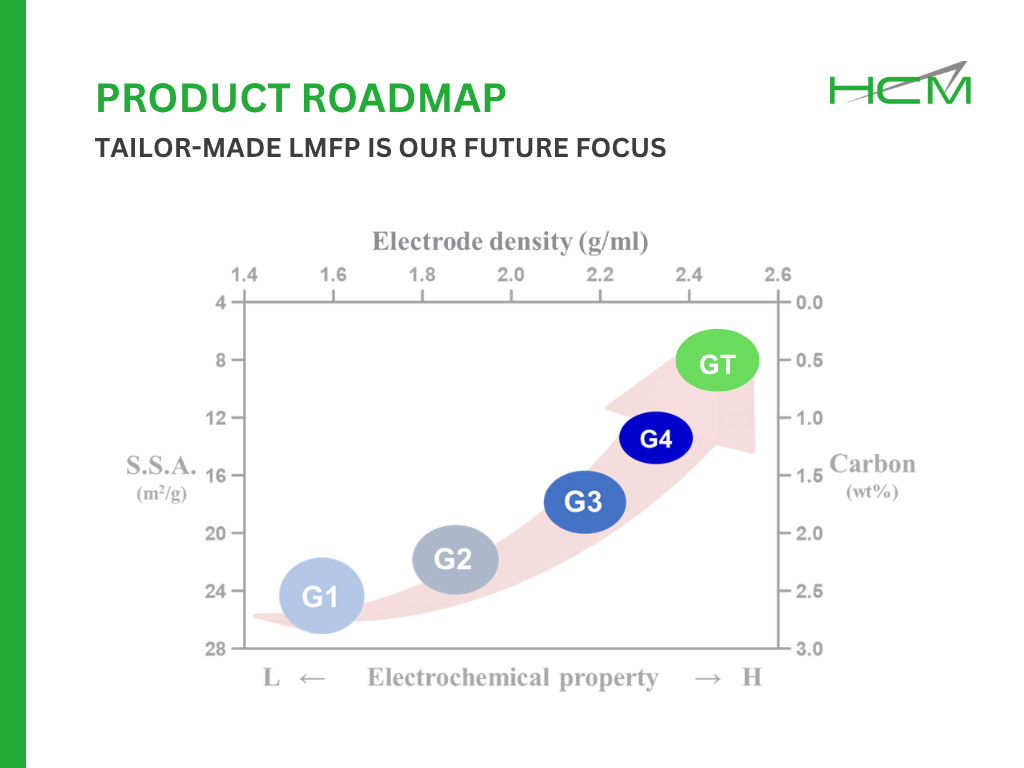

Since we started as a powder equipment manufacturer, we’ve developed deep expertise in particle engineering—skills that now set us apart from other material producers. Our GT grade is a prime example of how precision process control results in tailor-made #LMFP materials.

One of the core technologies behind this is our spray dryer, equipped with a new patented nozzle. What makes it stand out?

✅ Narrow PSD – Consistent morphology and size for superior electrochemical performance.

✅ High Efficiency – Optimized throughput and energy usage, thanks to a compact, high-output design.

✅ Customizable Output – Adjustable process parameters for precise control over particle design.

Because we design and build our own powder processing equipment, we have the flexibility to fine-tune production in house. That’s how we deliver the consistency, quality, and performance our customers expect from next-generation LMFP.

#HCM #BatteryMaterials #Cathode #SprayDryer #CAM #MaterialsEngineering #EnergyStorage #BatteryInnovation #EVs